|

|

|

|

|

Description:

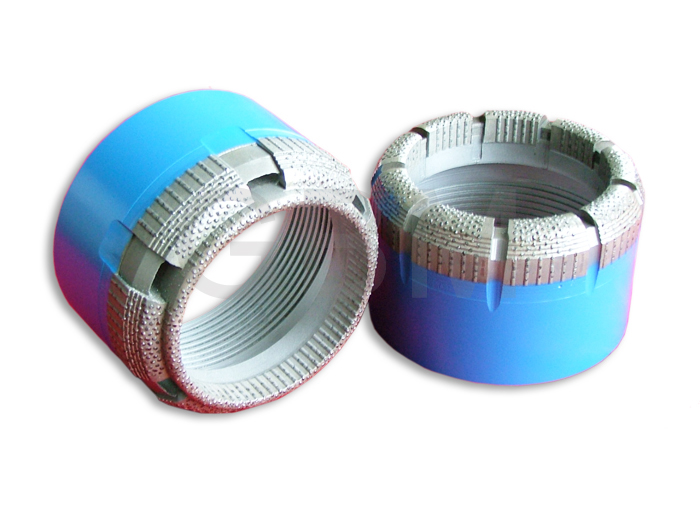

The surface-set diamond bit differs from the impregnated diamond typein that they are set with a single layer of natural drill diamond on the working surfaces of the bit crown in a pre-determined pattern. The diamonds are mounted in a bit crown powdered metal matrix body that is fused to a steel tool body or shank. The function of the bit crown matrix body on a surface-set bit is to tightly hold the diamonds in position throughout the operational life of the bit. Tungsten Carbide (T C) inserts can be provided on water ways where there is erosion of matrix in abrasive type formations. In most cases, surface set diamond bits will provide higher rates of penetration than impregnated diamond bitsin softer formations due largely to the greater degree of exposure of the individual diamond crystals. We makes the surface set core bits with the different size natural diamonds, different crown type for the different formation.

Category:

A range of surface set core bits are manufactured to the highest quality standards to give long service life and maximum penetration in soft to hard formations. The range includes a variety of diamond grades, stone sizes and face profiles enabling a cost effective solution to be taken for most conditions.

10/15 spc: Soft to Medium Formation

20/25 spc: Medium to Hard Formation

30/40 spc: Medium Hard to Hard Formation

40/60 spc: Hard Formation

60/80 spc: Hard to Very Hard Formation

(a) Semi Round Profile

(b) Round Profile

(c) Step Profile ( 4 step, 5 step and 7 step profile and customers request available)

They are AQ, BQ, BQ3, NQ, NQ2, NQ3, NQTT, HQ, HQ3, HQTT, PQ, PQ3, PQTT, T2 series, T6 series, DCDMA standard, European standard of 412, HWF, PWF, GEO S BORE, AW, BW, NW, PW, HWT, PWT, BQ rod shoe, NQ rod shoe, HQ rod shoe, BTW, NTW, NMLC, HMLC, TNW, LTK 48, LTK 60, AWT, AXT, NWD4 and oversized bits.

The customers request is available for us.